Extrusion Of Plastics for Beginners

Wiki Article

Extruded Plastic Profiles Can Be Fun For Anyone

Table of ContentsSome Ideas on Custom Plastic Extrusion Manufacturers You Should KnowThe Single Strategy To Use For Custom Plastic Extrusion ManufacturersIndicators on Plastic Extrusion Profiles You Should KnowSome Known Factual Statements About Custom Plastic Extrusion Manufacturers

As with any type of manufacturing procedure, the extruded account will certainly vary slightly throughout the process necessitating resistances on essential measurements. Resistances on plastic extrusions impact fit and also function, as well as the ideal time to start checking out tolerance needs is throughout the initial style stage. By functioning with Formtech early at the same time, we can supply style for making help including resistance requirements.For an extra comprehensive description regarding how tolerances impact rates, as well as a basic resistance overview, please visit this site. Mass thickness is specified as the weight each quantity of the plastics bought by Formtech for use in custom-made extrusion applications. Mass thickness effects flow and feed prices on the extruder, and also variations wholesale thickness of the plastic will cause variations in dimension so it is an essential consideration for custom-made extrusion production operations We discussed back stress above, and also the importance of having the proper quantity of back stress throughout the extrusion process for physical residential property control (extrusion of plastics).

As soon as the plastic compound departures the extrusion pass away in a pressed type, the compound will certainly loosen up, or increase a little. This is described as die swell. Die swell is material particular, suggesting for instance a vinyl (PVC) product will experience a various die swell than a Polyethylene or Polypropylene substance.

In the extrusion procedure cleaning materials out of barrels, screws and also plastic extrusion tooling requires time and boosts expense (https://my-store-d42713.creator-spring.com/). If product modifications are being made on the line from one job to the next, this might involve removing as well as cleaning the die, drawing the screw on the device to clean, and also cleaning out the barrel of the maker while the screws are out.

What Does Extruded Plastic Profiles Do?

As a matter of fact, the purging products are so stable they can even be left in the extrusion die throughout storage space, put back on the extruder the following time the task requires to run, and also began without time consuming cleaning. The typical compound will press the purge out of the die when it leaves.

There are truly 2 methods that can be utilized to achieve this feeding procedure - https://www.onlinewebmarks.com/author/k3ll3rpl4st8/. The material can be had in a receptacle straight over the feed-throat of the extruder and fed by gravity. The screws will then take in the optimum amount of product they can with every revolution of the device, and also this is called flooding feeding.

The trips of the screw are not completely loaded with every transformation of the maker. This is called starve feeding of the extruder, and also offers some advantages to the extrusion specialist in specific scenarios. By not loading the screw channel totally, it supplies more control to the specialist, as well as eliminates some other variables that can occur with flood feeding.

Unknown Facts About Plastic Extruded Profiles

For each change of a solitary screw device, there is some slippage back over the trips of the screw. This slippage is helpful for blending of materials and colorants, but it produces a possibility for some rising and variant with the screw transformation. With this holding true, differing stress as material comes off the screw can trigger this handling issue for the extrusion professional.Call today or email at [e-mail protected] for more details.

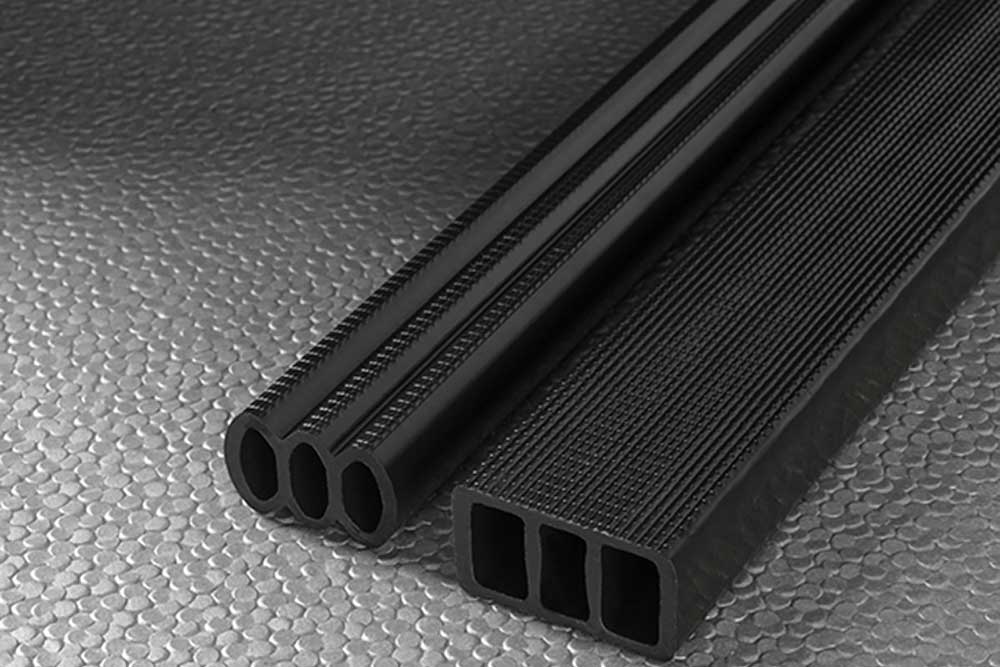

Such a range of items as well as utilizes matches to the vast range of compatible products and versatility that the extrusion procedure manages in developing custom profiles to fulfill your specific specifications. The plastic profiles produced in the extrusion procedure can be either adaptable or inflexible. Both deal advantages for various use situations (https://rebrand.ly/2mtf83p).

Everything about Custom Plastic Extrusions

While it eventually never prospered at its intended function, it however found regular usage in the auto industry in various other means, many thanks to its high liquid resistance as well as superb sealing performance. Automotive components generally made from Santoprene include weather condition seals, bumpers, wire jacketing, and a lot more. Santoprene TPV's remarkable securing building also makes it particularly beneficial in construction, where it can be made use of to make home window seals, tubing, electrical ports, and also wheel wheels (custom plastic profiles).We make use of cutting-edge technology in order to create the exact sort of extruded item you require. We are delighted to begin dealing with you soon!.

Manufacturing top quality items is as vital to us as attaining the highest possible criteria for client service. At the leading edge of our service are expert as well as specialized staff members who meet daily obstacles with cutting-edge suggestions - plastic extrusion manufacturers. Customer e-mail Personalized accounts/ shapes Dual Materials Hollows Rods Tubes Angles Bindings Brackets Caps Stations Clips Edgings Insulators J-Retainers/ J-Clips Moldings Retainers Seals Sleeves Spacers Straps T-moldings Tapes Tracks Cold Temperature Performance Shade Matched Dual-Durometer Convenience of Setting Up Embossed Flame Retardant Flexible High Gloss Heat Performance Interlocking Locking Matte Non-Contact Food Quality Ribbed Snap Fit Stiff Strength Textured Weatherability Aerospace Home Appliance Air/Water/Pollution Control Automotive Building Products Concrete Construction Electric Yard & Garden Logistics/ Transport Marine Office Solutions Point of Acquisition (POP) Show Numerous Providers Can Be Handled In-Line to Get Rid Of Secondary Procedures Adhesive/Transfer Tape Application Cut to Length Reducing Boring Embossing Heat Sealing Laminating Punching Directing Slotting Unique Packaging Welding AIAG Automotive Industry Activity Group ASME American Society of Mechanical Engineers ASTM American Culture for Testing and also Materials visit the website DOT Division of Transportation FDA Food as well as Medicine Administration FMVSS Federal Motor Automobile Safety Requirements MIL-STD Military Specifications SAE Culture of Automotive Engineers UL Underwriters Laboratories ISO International Organization for Standardization.

Report this wiki page